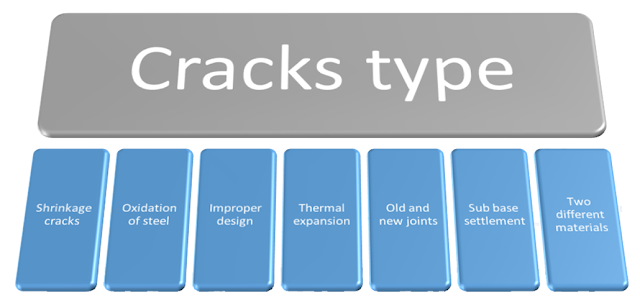

Let’s start with, what are the types of cracks? that is, what are the reasons for cracks in concrete? basically, are the following types of cracks, to understand properly, we have made a flow chart.

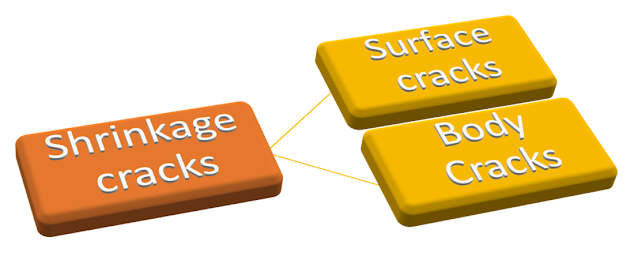

Now Shrinkage cracks are the cracks that develop when water gets out from the concrete. The concrete hardening and strength-gaining process are too long, but water finds it way sooner. Shrinkage cracks are of two types 1) surface shrinkage cracks and 2) body shrinkage cracks. You can see it in the flow chart.

Surface cracks occur due to the evaporation of surface water. Now, these cracks are not so deep but they can be in huge quantities.

Precaution: -

- Use less water

- Do not do excess vibration

- Start immediate curing

Concrete body cracks are the cracks that develop in a later stage due to excess water in concrete which tries to come out and leaves the cracks, these cracks are deeper and sometimes dangerous too.

Precautions

- Use Less water

- Do proper missing

***

***

Oxidation Crack: - In concrete, we put reinforcement (steel) for the tensile load. Now when water or air trapped in concrete come in contact with iron (steel) it starts trusting and starts to swell, Due to this expansion cracks are developed. This is the most dangerous stage.

Precautions

- Proper vibration should be done in concrete

- Immediate hole (honeycomb) should be packed after DE shuttering

Improper design: - In this case cracks might be the indication of structural failure. Steel reduces the cracks. So, if the cover is not properly to deign or Loaded more structures will bend and give cracks.

Precautions

- Proper Design Consultants should be hired

- The building should be used to be design load

- The building should be increased as per design criteria.

Thermal Expansion is another major reason for cracks. Concrete also expands and contracts as per the regular member, but as a brittle member concrete gets cracks if there is tension or gets the space to expand. For longer member joints are provided to act as an induvial member. Commonly seen in bridges and compound walls.

Precautions

- Concrete structure lengths more than 40 meters need a gap of 10 mm to 15 mm for its expansion (this expansion joint is filled with elastic / epoxy material)

- None of the connectivity should be there in the structure to make it properly move

- In the case of flat surfaces like roads or flooring, the segment of 4.0 m X 4.0 m should be there. This area should be increased.

Old and New joints: - Mostly at the time of extension or renovation, this situation occurs when we have to connect the old concrete to new concrete. But due to the nonbonding of old and new cracks occurs, secondly, new concrete gets shrunk which leaves the gap or cracks.

Precautions

- At the time of old and new joint of concrete make the old concrete rough, so that it can take proper grip.

- Apply Epoxy bond to make concrete stick to old concrete.

Sub-Base Settlement Cracks: - These cracks are developed due to the settlement of sub-base, that is soil. As we do frame structure nowadays, the settlement of one area does not allow to fail the structure, but as the tension is develop cracks are also developing in the structures.

Precautions

- All R.C.C structures should rest on the hard strata.

- Compaction is very necessary for the loose soil.

- Compaction should be done layer-wise at a maximum of 300 mm.

Two Different materials: - Usually this is seen at the time of concrete and steel, in roofing areas,s or in structural beams with concrete

Precautions

- Making anchoring part in steel

- Entering the sheet in concrete with more depth.

- Make a deep groove to avoid water

***

***

How to repair cracks

Now seeing the above reason for cracks, we have to adopt the manner of repairing the cracks. The table will clear the repair manner

|

Type of Cracks |

Repair manner |

|

Shrinkage Cracks |

Crack filler |

|

Oxidation of steel |

Remove the loose concrete and do a painting of exposed steel with zincromate, and fill the concrete |

|

Improper design |

Nonrepairable |

|

Thermal expansion |

Fill the gap with bitumen and cover the area with bitumen |

|

Old and new concrete joint |

Inject the concrete |

|

Sub Base Settlement |

Inject the concrete and then crack fill |

|

Two different materials |

Applying Bitumen tape to the surface |

Maintenance of Cracks and future problems

This might be a headache if the cracks or gap is small and not able to find out from which leakage is coming. For this you can use the ink method to identify the exact area of the gap, in this method different color of ink is applied on the surface, and ink will travel inside the concrete and fill should the outlet, mainly this method is used by the plumber

Maintenance of cracks is done in summer session, at that time water and area comes out making the cracks bigger, the second reason for summer is, that we can dry surface, easily we can apply two coats of solution of cracks.

Chemical for cracks repair

For the best chemical of crack seal or repair work you can join this website ( follow the website ), once you have clicked the follower button. Just comment below this article and we will give you free solutions

What not to do in cracks:-

1) Most of the time people do big mistakes by filling only the cement slurry in the cracks or gaps. First, it will not go deep inside, secondly due to the heat of hydration again cracks will appear.

2) Filling silicon in the gap, silicon also does not go inside, and in hot weather, it gets hard and comes out

Facts:-

1) Road concrete works allow 10 % cracks.

2) Floor r.c.c panels should not be more than 4.5 lengths.

3) To avoid surface cracks groove is cut in the floor within 8 hours after casting.

4) Almost 55 % of cracks develop due to bad workmanship.

5) There is a myth that cracks always come in new construction if you do the work quality also.

Cracks in concrete can occur due to a variety of reasons, including shrinkage, settlement, weathering, heavy traffic, overloading, or improper construction. Here are some common types of cracks in concrete:

Plastic shrinkage cracks: These cracks are caused by rapid drying of the surface of freshly poured concrete, which results in the surface pulling apart and forming small cracks.

Drying shrinkage cracks: As concrete dries, it shrinks, and this can cause cracks to appear in the concrete.

Settlement cracks: These occur when the ground underneath the concrete settles or shifts, causing the concrete to crack.

Overload cracks: If the concrete is subjected to heavy loads or excessive pressure, it can cause the concrete to crack.

Freeze-thaw cracks: When water gets into concrete and freezes, it expands, causing the concrete to crack.

Chemical reaction cracks: Certain chemicals can react with concrete and cause it to crack over time.

To prevent or minimize cracking, it's important to ensure that the concrete is properly mixed, placed, and cured. In addition, using reinforcing steel or fiber can help to reduce cracking. Regular maintenance and repairs can also help to prevent small cracks from turning into larger ones.

The method used to repair a crack in concrete will depend on the severity and type of crack. Here are some general steps for repairing concrete cracks:

Clean the crack: Use a wire brush or a high-pressure water jet to remove any debris or loose material from the crack.

Prepare the crack: For larger cracks, use a chisel and hammer to widen the crack to a uniform width and depth. This will help the repair material to adhere better to the surface.

Fill the crack: Fill the crack with a suitable repair material such as epoxy, polyurethane, or cement-based filler. Follow the manufacturer's instructions for mixing and applying the product.

Smooth the surface: Use a trowel or putty knife to smooth the surface of the repair material and ensure it is level with the surrounding concrete.

Allow to cure: Let the repair material cure according to the manufacturer's instructions. Depending on the product used, this could take several hours or several days.

Seal the surface: Apply a concrete sealer to the repaired area to protect it from water damage and further deterioration.

It's important to note that some cracks may require professional repair, especially if they are caused by structural issues or if they are extensive. Consulting with a concrete repair specialist may be necessary for larger or more severe cracks.

Reviewed by Rehan Qamar

on

June 16, 2022

Rating:

Reviewed by Rehan Qamar

on

June 16, 2022

Rating:

No comments:

Please click on follower button