There are several types of fencing, each with its own advantages and disadvantages. Here are some of the most common types:

Chain-link fencing: This is a popular choice for residential and commercial properties because it is relatively inexpensive, durable, and requires minimal maintenance.

Chain-link fencing is a popular type of fencing that is made from galvanized steel wire that is woven into a diamond-shaped mesh pattern. It is commonly used to secure residential and commercial properties, as well as public spaces such as parks and playgrounds. Here are some advantages and disadvantages of chain-link fencing:

Advantages:

Cost-effective: Chain-link fencing is one of the most affordable types of fencing.

Durability: It is strong and durable, and can withstand harsh weather conditions.

Low-maintenance: It requires very little maintenance and can be easily cleaned with a hose.

Visibility: The open mesh design provides visibility and does not block natural light.

Disadvantages:

Appearance: Chain-link fencing is not the most aesthetically pleasing option and may not complement certain styles of homes or properties.

Lack of privacy: The open mesh design does not provide much privacy, although it can be partially obscured by adding privacy slats.

Security: While chain-link fencing can provide a physical barrier, it may not be the most secure option as it can be easily cut or climbed over.

Rust: Over time, the steel wire can rust, which may compromise the strength and appearance of the fence.

Wood fencing: This is a classic choice that offers a traditional look and feel. It is available in a variety of styles and can be stained or painted to match your home's exterior.

Wood fencing is a popular option for residential properties because it offers a traditional look and feel. It can be customized to fit any style or design preference, and it comes in a variety of sizes and colors. Here are some advantages and disadvantages of wood fencing:

Advantages:

Aesthetics: Wood fencing offers a natural and classic look that can complement any type of property.

Customizable: It can be easily customized to fit any size or design preference.

Privacy: Wood fencing can provide excellent privacy depending on the style and height.

Durability: High-quality wood fencing is durable and can last for many years with proper maintenance.

Disadvantages:

Maintenance: Wood fencing requires regular maintenance such as staining or painting, sealing, and periodic repairs to maintain its appearance and durability.

Cost: Wood fencing can be more expensive than other types of fencing such as chain-link or vinyl.

Vulnerability: Wood fencing is vulnerable to rot, termites, and other pests, which can compromise its structural integrity.

Installation: Wood fencing can be more difficult to install than other types of fencing, which can increase installation costs.

Vinyl fencing: This type of fencing is durable and low-maintenance. It is available in a variety of styles and colors, making it a popular choice for homeowners who want a modern look.

Vinyl fencing is a popular option for residential and commercial properties because it is low-maintenance, durable, and versatile. It is made from a type of plastic called PVC (polyvinyl chloride), which is lightweight, flexible, and strong. Here are some advantages and disadvantages of vinyl fencing:

Advantages:

Low-maintenance: Vinyl fencing requires very little maintenance and can be easily cleaned with a hose and mild detergent.

Durability: It is strong and durable, and can withstand harsh weather conditions, including extreme temperatures and high winds.

Versatility: Vinyl fencing is available in a variety of styles, colors, and textures, and can be customized to fit any design preference.

Longevity: High-quality vinyl fencing can last for many years with minimal upkeep.

Disadvantages: Cost: Vinyl fencing can be more expensive than other types of fencing, although it is more affordable in the long run due to its low maintenance and long lifespan.

Installation: Vinyl fencing can be more difficult to install than other types of fencing, which can increase installation costs.

Limited repair options: Vinyl fencing is not easily repaired, and damaged sections usually need to be replaced.

Appearance: Some people do not prefer the appearance of vinyl fencing as it can look artificial or "plastic".

Aluminum fencing: This is a low-maintenance option that is durable and comes in a variety of styles. It is also lightweight and easy to install.

Aluminum fencing is a popular option for residential and commercial properties because it is durable, low-maintenance, and customizable. It is made from lightweight, corrosion-resistant aluminum alloy and is available in a variety of styles and colors. Here are some advantages and disadvantages of aluminum fencing:

Advantages:

Low-maintenance: Aluminum fencing requires very little maintenance and can be easily cleaned with a hose and mild detergent.

Durability: It is strong, durable, and resistant to rust and corrosion, making it an ideal choice for coastal areas or humid environments.

Customizable: Aluminum fencing is available in a variety of styles, colors, and finishes, and can be customized to fit any design preference.

Lightweight: It is lightweight and easy to install, which can reduce installation costs.

Disadvantages:

Cost: Aluminum fencing can be more expensive than other types of fencing such as chain-link or wood.

Limited privacy: Aluminum fencing provides limited privacy as it is usually made with pickets spaced apart from each other.

Vulnerability to damage: While aluminum is durable, it can be easily dented or damaged by heavy impact.

Security: Aluminum fencing may not be the most secure option as it can be easily cut or climbed over.

Wrought iron fencing: This is a classic and elegant option that is durable and long-lasting. It requires regular maintenance to prevent rust and corrosion.

Wrought iron fencing is a classic and elegant option for residential and commercial properties. It is made from iron that is heated, twisted, and bent into decorative designs and patterns. Here are some advantages and disadvantages of wrought iron fencing: Advantages: Aesthetics: Wrought iron fencing provides a classic and elegant look that can complement any type of property.

Durability: It is strong, durable, and resistant to weather conditions, making it an ideal choice for outdoor use.

Security: Wrought iron fencing provides a high level of security due to its strength and durability.

Customizable: It can be easily customized to fit any size or design preference.

Disadvantages:

Cost: Wrought iron fencing is one of the most expensive types of fencing due to its material cost and intricate design.

Maintenance: It requires regular maintenance such as painting and rust removal to maintain its appearance and durability.

Vulnerability to rust: Wrought iron fencing can be vulnerable to rust, which can compromise its structural integrity.

Weight: Wrought iron fencing is heavy and can be difficult to install, which can increase installation costs.

Electric fencing: This type of fencing is often used to contain livestock or pets. It uses a low-voltage electric shock to deter animals from crossing the boundary.

Electric fencing is a type of fencing that uses electrical shocks to deter animals or people from crossing a boundary. It is commonly used in agriculture to contain livestock, but it can also be used for security purposes. Here are some advantages and disadvantages of electric fencing: Advantages: Deterrent: Electric fencing provides a strong deterrent against trespassers and can effectively contain livestock.

Low cost: It can be more affordable than other types of fencing such as wood or wrought iron.

Customizable: It can be easily customized to fit any size or design preference.

Easy installation: Electric fencing is relatively easy to install and can be done without professional help.

Disadvantages:

Safety concerns: Electric fencing can be dangerous if not installed and maintained properly, and it can cause injury or death to animals or people.

Maintenance: It requires regular maintenance to ensure that it is functioning properly and safely.

Limited use: Electric fencing is typically used for agricultural or rural purposes and may not be suitable for urban or residential areas.

Legal restrictions: In some areas, there may be legal restrictions on the use of electric fencing, so it is important to check local regulations before installing.

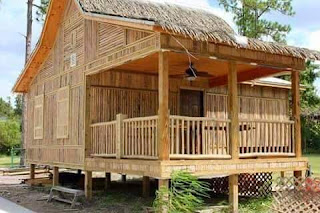

Bamboo fencing: This is a sustainable and eco-friendly option that provides privacy and a natural look. It is easy to install and maintain, but may not be as durable as other types of fencing.

Bamboo fencing is a type of fencing that is made from bamboo, a fast-growing and renewable resource that is environmentally friendly. It is becoming increasingly popular as an alternative to traditional wood or vinyl fencing. Here are some advantages and disadvantages of bamboo fencing:

Advantages:

Eco-friendly: Bamboo is a sustainable and renewable resource, making bamboo fencing an environmentally friendly option.

Aesthetics: Bamboo fencing has a unique and natural look that can complement any type of property.

Durability: Bamboo is strong and durable, and when properly treated and maintained, it can last for many years.

Cost: Bamboo fencing can be more affordable than other types of fencing such as wood or wrought iron.

Disadvantages:

Vulnerability to weather: Bamboo fencing is vulnerable to weather conditions and can rot, fade, or split if not properly treated or maintained.

Limited privacy: Bamboo fencing provides limited privacy as it is usually made with pickets spaced apart from each other.

Limited availability: Bamboo fencing may not be readily available in all areas and may require special ordering or shipping.

Limited security: Bamboo fencing may not provide the highest level of security as it can be easily cut or climbed over.

There are many fencing contractors in the USA, and it can be helpful to research and compare them before selecting one to work with. Here are a few ways to find fencing contractors in the USA:

Online directories: Websites like HomeAdvisor, Angie's List, and Yelp allow you to search for fencing contractors in your area and read reviews from previous customers.

Local business listings: Check your local phone book or online business directories like Google My Business to find fencing contractors in your area.

Referrals: Ask friends, family, or neighbors who have recently had fencing work done for recommendations.

Social media: Look for local fencing contractors on social media platforms like Facebook or Instagram.

Once you have found potential fencing contractors, it is important to ask them for references, look at their portfolio of work, and get a written estimate for the project. Additionally, it is important to check if they are licensed, insured, and have any complaints filed against them with the Better Business Bureau or other consumer protection agencies.

.jpeg)